WHAT ARE MEMBRANE SWITCHES?

Membrane switches are electrical switches that turn circuits on or off. Operating as touchscreens, they enable clear communication between device operators and electronic devices. Membrane switches are part of the growing field of technological input devices that include toggle switches, plastic keyboards, touchscreens, and other types of control systems, and can be found on many medical devices.

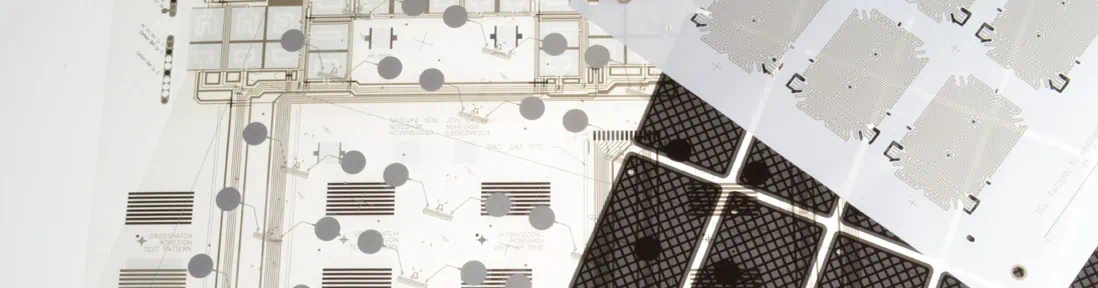

Membrane switches differ from mechanical switches mainly in form. They consist of an electrical circuit printed on polyethylene terephthalate (PET) or indium tin oxide (ITO) with copper, silver, or graphite ink, whereas mechanical switches are constructed entirely from metal or plastic parts.

WHICH MEDICAL DEVICES USE MEMBRANE SWITCHES?

Membrane switches’ minimal weight, low profile, durability, and ease of maintenance make them a popular choice for medical device makers. Medical switch keyboards can be found on:

- IV pumps: These devices deliver blood, medication, and other fluids to patients intravenously. IV pumps can incorporate full alphanumeric medical switch keyboards to help adjust parameters such as infusion rate and volume.

- Oxygen concentrators: Oxygen concentrators compress atmospheric oxygen and deliver it to patients suffering from conditions such as hypoxia. Membrane switches assist with flow control and mode selection, and they also display backlight applications.

- Vital signs monitors: Vital signs monitors report patients’ vital functions to observers. Membrane switches in vital signs monitors typically include features for recording, printing, and menu control.

- Defibrillators: These medical devices rescue patients in cardiac arrest by delivering an electric pulse or shock to the heart. Defibrillators must be able to operate in diverse conditions, so membrane switch keypads should be designed with durability in mind. Typical defibrillator membrane keypad functions include energy level selection, energy level charging, and shock administration.

- Hospital beds: Membrane switches are used in hospital beds to make adjustments to the bed position and patient posture, allowing medical personnel to quickly attend to their patients’ needs.

BENEFITS OF MEMBRANE SWITCHES

Membrane switches are highly valuable to the user interfaces of many different kinds of medical devices. Some of their benefits include:

- Cleanliness: Integrated antimicrobial film technology ensures medical-grade cleanliness for devices with membrane switches. This film contains special compounds that inhibit or destroy the growth of bacteria, thus preventing bacterial spreading and contamination while allowing ease of operation for professionals.

- Shielding: Membrane switch designs protect against electrostatic discharge by using double-sided polymer circuitry to redirect and ground unwanted discharges. This shielding effect blocks the intrusion of unwanted signals, preventing equipment malfunction.

- Graphics: Membrane switches can be customized to meet almost any aesthetic specification. Diverse combinations of color pallets and graphic overlays enhance product differentiation. In addition to aesthetics, membrane switches possess a 180° viewing angle and further integrate indicator lights to improve visibility.

- Sealability: Membrane switches can be sealed against the intrusion of water, chemicals, and other external substances. In addition to the membrane’s inherent waterproof properties, membrane switches incorporate full-perimeter seals or gaskets for additional protection of the device’s internal circuitry.

- Lighting: Backlit panels ensure that membrane switches are visible in low-light environments. LED and electroluminescent panels can communicate with operators at a distance. Backlighting also allows for ease of operation and comprehension due to the higher resolution it achieves.

- RoHS compliance: All membrane switches comply with Restriction of Hazardous Substances (RoHS) policies due to their makeup of PET and ITO compounds.

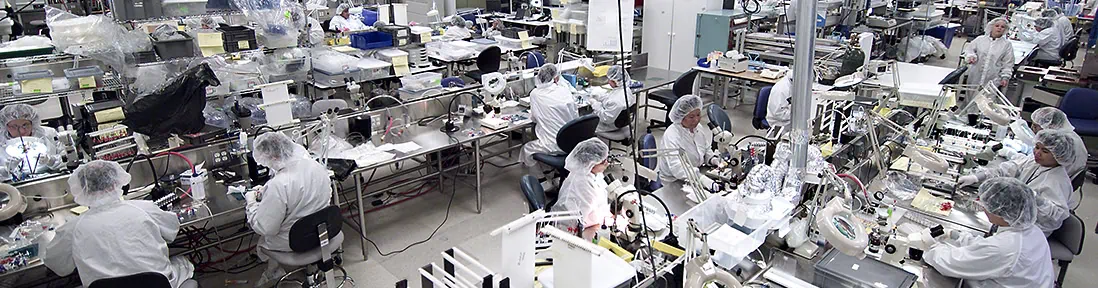

At Eastprint, an East West Business, we draw on 40 years of experience to develop high-quality membrane switches for use in medical devices. Our engineering expertise and broad range of capabilities enable us to offer a diverse array of membrane switch keyboards for all kinds of medical electrical devices. We have two manufacturing facilities that are ISO 13485 certified and offer low-cost manufacturing in North America.

If you would like to learn more about our membrane switches and how they can benefit your medical device, contact our technical team and request a quote today.