At Eastprint, an East West Business, we manufacture screen printed electrode biosensors for use in cardiac pacing, defibrillation, and ECG applications. We worked side-by-side with both the client and material suppliers over a two-year development cycle to engineer this groundbreaking product. We overcame the issues associated with the cost of manufacturing a high-quality solution and developed economies of scale that have allowed the client to deeply penetrate the market and gain a competitive share.

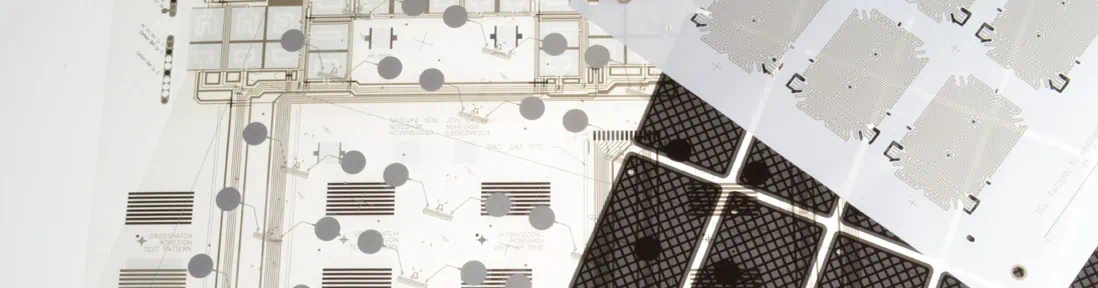

This electrode had a set of highly technical specifications and production leveraged our industry-leading expertise in printing conductive polymers on flexible substrates. We developed a pioneering method for depositing a silver/silver chloride ink system on a polyester substrate at a level to survive the rigors of its end use as a pacing, defibrillation, and ECG electrode while offering a level of radio-translucency that allowed for unobstructed visual x-rays while in clinical use.

Although the process appears simple, it is far from conventional. We engineered a highly developed system of process controls at every step of production, which involved silk screen printing, thermal cure, and clamshell die cutting. Our methods ensured accurate and repeatable production with exceptionally high yield rates to keep costs to a minimum. In addition to statistical process controls and visual inspection of the exposed conductive surface, quality metrics includes assessment of conductivity, deposition thickness, and adhesion strength. We also invested in a custom system to package these sensitive devices.

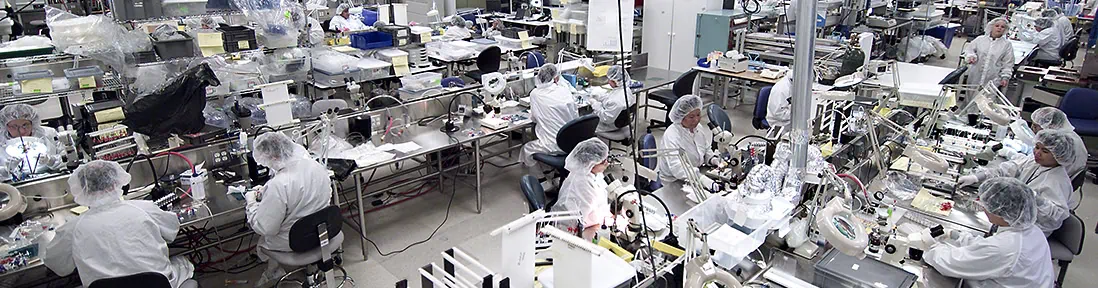

Everyone in our facility is involved in the production of this electrode at the rate of half-million units per year. Our workforce takes great pride in their contribution towards our successful partnership with this company. Over the past 20 years, our annual business with them has grown substantially due to our ability to provide the highest quality products, delivered on time, and at very fair and reasonable costs.

Contact us today if you would like to learn more about this project or our production capabilities.

Pacing, Defibrillation & ECG Electrodes Project Highlights

- Project Description

Pacing – Defibrillation – ECG Electrodes

- Capabilities Applied/Processes

- Primary:

Screen Printing - Secondary:

Die-Cutting

- Primary:

- Equipment Used to Manufacture Part

Flat Bed Silk Screen Printer

Thermal Cure Oven

Clam-Shell Die Cutting Press

- Overall Part Dimensions

3.572″ x 4.881″ Anterior, 3.032″ x 5.891″ Posterior

- Tightest Tolerances

+/- .005″

- Material Used

Polyester, Silver/Silver Chloride Ink System

- Material Finish

Exposed Conductive Surface

- Industry for Use

Medical Device

- In Process Testing/Inspection Performed

- SPC

Conductivity

Deposition - Adhesion

Visual

- SPC

- Delivery Location

USA

- Standards Met

ISO-13485

RoHS

REACH