At Eastprint, an East West Business, we have been an industry leader in providing custom keyboard assemblies for over 35 years. Our expertise in membrane switch technology is unsurpassed in the industry, making us one of the most trusted suppliers of user interface contract manufacturing services. Providing high quality, reliable keyboards, keypads, front panels, and more, we offer a broad variety of design and assembly options, user-specific features, and general interface capabilities. Customers rest assured that when they order from Eastprint, an East West Business, they are receiving cost effective solutions that meet or exceed the most stringent industrial standards.

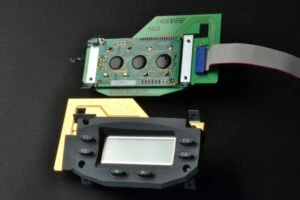

Our user interface contract manufacturing services encompass a broad array of options to enhance keyboard assemblies. From engineering and design assistance to full production at the prototype, low, medium, or high volume level, our user interfaces fulfill every customer specification with economy and quality. Ridged and flex surface mounts are available, as well as electronic modules and turnkey front panel assemblies. A full breadth of design and assembly options are also available to maximize user interface. Some of these include dead front graphics, display integration, interchangeable graphics, metal backers, cable assemblies, and backlighting. Other options include optically laminated windows, graphic embossing, in-mold decorating, plastic bezels, tinted windows, machined or cast aluminum housings, and many others.

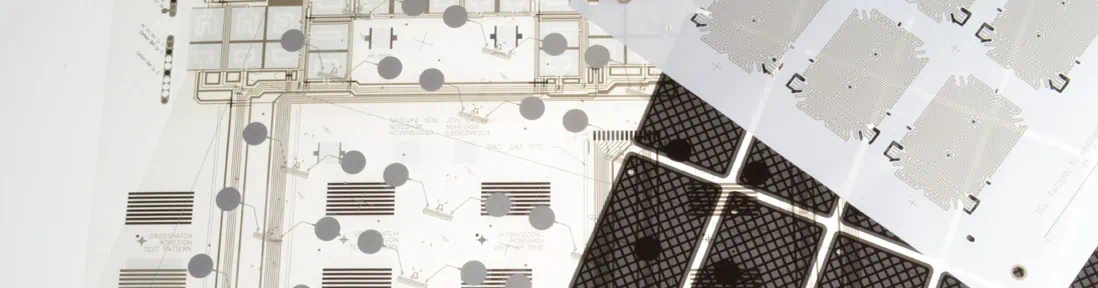

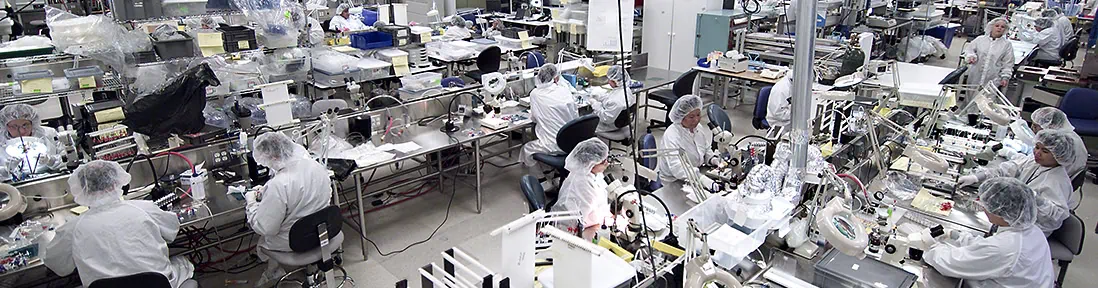

We offer adhesive lamination for membrane switches to rigid surfaces, making a critical impact in improving the long-term reliability of switches and LEDs. Our deep level of experience in this area allows us to offer laminations that provide a fully functional and tested switch assembly that is already laminated to a rigid backer, providing functionality for years. In addition to adhesive lamination, a number of other user-specific features are available. Some of these include Capacitive touch, metal dome, PushGate™, tactile graphic and polydome switches, as well as silicone rubber keypads and overlays and custom test fixtures and programs. Our materials are made using the finest quality inks, plastics, and metal alloys; they are assembled by hand, on an assembly line, in a work cell as well as with semi- and fully automated processes.

It is our goal at Eastprint, an East West Business to continuously improve our customers’ satisfaction. To this end, we employ the most innovative products and services, all the while never compromising quality. We are fully ISO 9001 and ISO 13485 certified and ITAR compliant, guaranteeing that our manufacturing processes are occurring at the highest level at every step.

For more information about our user interface contract manufacturing, please see the below table or contact us directly.

User Interface Contract Manufacturing Capabilities

- General Capabilities

User Interface Contract Manufacturing

Turnkey Front Panel Assemblies

Low Cost Labor Assembly

Surface Mount (Ridged and Flex)

Automation

Electronic Modules

Low, Medium and High Production Volume

Prototyping, Rapid or Production Quality

Design Assistance

Engineering-CAD/3D Modeling

- Design and Assembly Options

Dead Front Graphics

Display Integration

Interchangeable Graphics

Metal Backers

Cable Assemblies

Back Lighting

Optically Laminated Windows

Graphic Embossing, In-Mold Decorating

Plastic Bezels

Tinted Windows

Touch Screens Integration

PCB Rubber Key Pad Assemblies

Machined or Cast Aluminum Housings

- User-Specific Features

- Metal Dome, PushGate™, Tactile Graphic and Polydome Tactile Feel Switches

- Silicone Rubber Keypads and Overlays

- Discreet Backlighting by LEDs and Custom Light Guides

- Custom Test Fixtures and Programs

- Conductive Shields, Printed Silver or Carbon Inks, Metallized Mylar® or ITO (indium tin oxide) Films offer EMI/RFI and ESD Protection

- Surface-mounted Components on Flexible Circuits (LEDs, Resistors, Capacitors and Discrete Memory Chips)

- Polyester or Polycarbonate Film Graphic Overlays with Hard Coating and/or Surface Texturing

- Materials

- Silver Conductive Inks

Translucent Conductive Inks

Thick Film Polymer Inks

FR-4 Ridged Printed PCBs - Polyester

Polyimide

Plastic Resins

Metal Alloys

- Silver Conductive Inks

- Assembly Methods

Automated and Semi Automated Sheet Fed

Roll to Roll Printing

Automated Pick and Place

Soldering

Roll and Hand Lamination

Work Cells

Assembly Line Production

*Low Cost Labor Assembly

- Quality Assurance

ISO 9001

ISO 13485 (Medical)

ITAR Compliant

Eastprint, an East West Business Quality Policy:

To continuously improve customer satisfaction through quality planning, process improvement and innovative products.

- Industry Focus

- Printed Electronics

Medical

Wearable Electronics

Industrial Control - Appliance

Consumer

Aerospace

Military

- Printed Electronics