Since 1978, Eastprint Incorporated – an East West Company has been a pioneer in the field of printed electronics. While we design and manufacture membrane switches and offer a wide range of other human machine interface (HMI) technologies, our passion for printed electronics has led us to develop new and innovative processes and technologies, such as custom in-mold electronics.

What Are In-Mold Electronics?

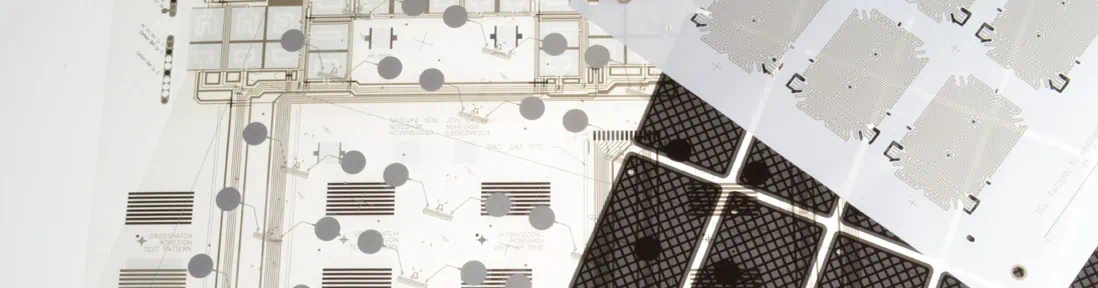

In-mold electronics (IME) technology consists of conductive inks which are printed onto flexible film substrates. The printed designs are then thermoformed into 3D forms and die cut from the sheet. Next, the formed parts are placed in a mold and injected with plastic to produce a more rigid structure. The end product is a small, lightweight, and has a customized electronic circuit.

Compared to traditional circuit products, IME is available at lower costs and produces less waste. However, while there is widespread interest in the technology, few companies are prepared to invest in its production before leaders in the field demonstrate its potential.

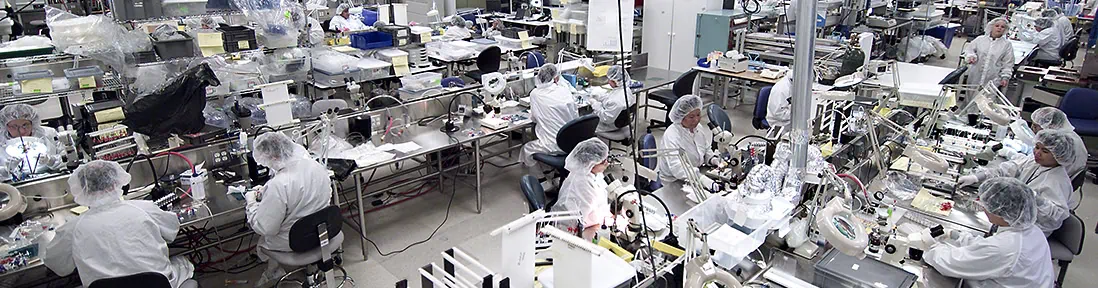

Eastprint Incorporated – an East West Company, on the other hand, has a history of being at the forefront of new printed electronics technology, having been one of the first companies involved in the industry. With our knowledge and experience gained throughout our years in the business, we are able to offer a comprehensive collection of compatible materials, including films, graphic inks, silver inks, dielectric inks, and conductive epoxy. These qualities have also helped us forge strong, collaborative relationships within the industry.

Having established a thorough understanding of the design and manufacturing principles that apply to IME—such as trace thickness and circuit resistance values—we are well-prepared to take the lead in developing and raising awareness of this new electronic interconnect attachment technology.

The Benefits of In-Mold Printed Electronics

IME technology offers several benefits to the printed electronics industry, including a more lightweight design, lower material and production costs, and a smaller environmental footprint. More specifically, it provides the following advantages over traditional electronics:

- Smaller, more lightweight design: IME combine sensors, LEDs, connectors, and circuitry all on a functional plastic form, eliminating the need for old-style bulky printed circuit boards. This innovative technology offers the same functionality with up to a 70% reduction in weight, which opens up countless possibilities for products that use IME.

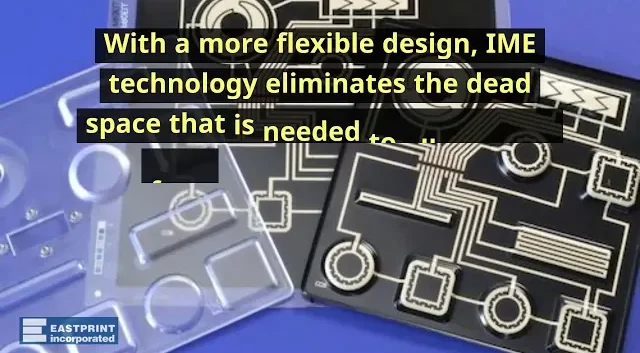

- Design optimization: With a more flexible design, IME technology eliminates the dead space that is needed to allow room for wires and connectors. Available in both 2D and 3D forms, it offers a wide range of design options for capacitive switches with high flexibility regarding design and graphic artwork.

- Lower costs: Another advantage of this technology is its lower production costs. The assembly is more automated than other user interface technologies and requires fewer raw materials. Additionally, it provides a single connection point, eliminating the need to add wires behind the console. All together, IME can save as much as 30% on costs.

Eastprint, an East West Business Offers In-Mold Electronics Production Services

Offering greater design flexibility and increased functionality in smaller packages at lower costs, in-mold electronic technology has immense potential in the design and manufacturing industries. Our strong, pioneering screen printed electronics background uniquely poises Eastprint Incorporated – an East West Company to be a leader in IME development.

For more information about in-mold electronics, contact us today. To see how we can meet your unique needs, request a quote.