Touchscreens aren’t a single technology. Several approaches are in wide use, but the two leading ones in mobile devices being resistive and capacitive screens. Capacitive screens may offer more value and functionality for the end user.

As the name suggests, a capacitive screen uses the principle of electrical capacitance. The screen senses the proximity of an electrically conductive object, such as the user’s finger, at a particular point, requiring only a light touch. Electrical current doesn’t flow into the user; rather, the electric field in the screen pushes against the electrons in the finger. They’re also good for handling gestures and multi-touch input.

Capacitive touchscreens are widely used in mobile phones and tablets, as well as appliances, kiosks and ATMs. The first consumer phone with the technology was the LG Prada, announced in 2006. The iPhone followed in 2007. The screens started out as a luxury feature, but today they dominate the smartphone market, though they aren’t typically used for cheaper phone models.

Capacitive Touchscreens vs. Resistive Touchscreens

Resistive screens require physical pressure. The top layer is a flexible material, such as a polycarbonate film. When the user presses down on it, the conducting material which lines the screen comes in contact with the conducting material on the rigid layer, usually glass, below. This type of screen requires a fairly strong touch, which makes it harder to slide the finger over the screen. Resistive screens typically cannot handle multi-touch input.

Conversely, a capacitive touchscreen doesn’t have a mechanical component. The top layer is fabricated from rigid glass or plastic. It can sense capacitance at more than one point at a time, and it can follow a light touch as it moves along the screen.

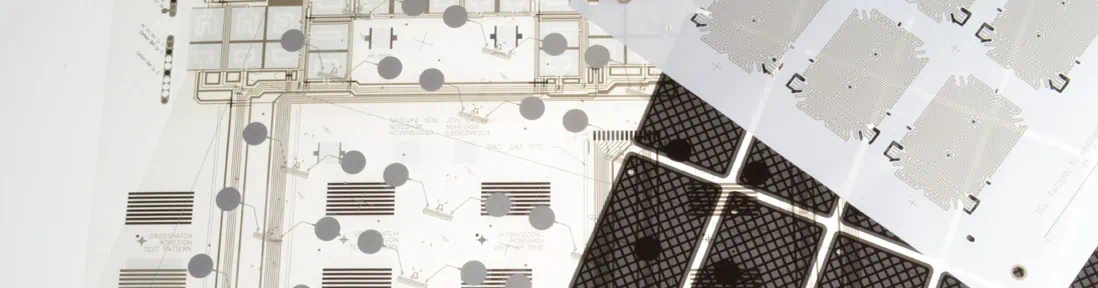

Surface and projective capacitive screens are the two major types currently in use. Surface capacitive screens have an electrode at each corner and measure the position of a touch by its distance from the corners. Projective screens use an array of electrodes under the top layer.

Capacitive screens are sometimes criticized for their inability to be interactive with a normal, electrically inert stylus. However, they work well with a conductive stylus, and many suitable products.

A capacitive touch screen panel offers five distinct advantages over resistive screens:

- Durability

The screen doesn’t need to bend under pressure as it is made of a rigid material. This means it won’t wear down with use. Heavily used points on a resistive screen may become permanently deformed over time, making them less responsive. - Visibility

Capacitive screens generally feature better clarity and contrast, especially in bright light. The combination of durability and visibility is especially advantageous in outdoor applications with heavy use. - Reliability

A cracked capacitive screen will usually continue to operate until it can be replaced. A crack generally makes a resistive screen stop working, since it can’t maintain the proper tension. - Multi-touch

While some resistive screens support multi-touch capability, making it work is complicated, so most only support single touch usage. Multi-touch input works better with capacitive screens. Sliding and gestures also come more easily on a capacitive touchscreen, since only a light touch is necessary. - Future-proof

Capacitive touchscreens are considered the industry standard, due to the benefits they offer the user. Multi-touch is increasingly in demand, even in less expensive devices. Moving to capacitive screens ultimately means keeping pace with the current direction of technological trends.

A Wealth of Opportunities

Capacitive touch screen panels offer a better user experience for most applications when compared to alternative technologies. Consumers and industrial workers alike have come to expect more than just button-tapping, and screens with multi-touch ability and easy sliding and dragging are positioned to offer the most features. As such, capacitive touchscreens represent the future of touchscreen technology and are suitable for nearly any purpose.

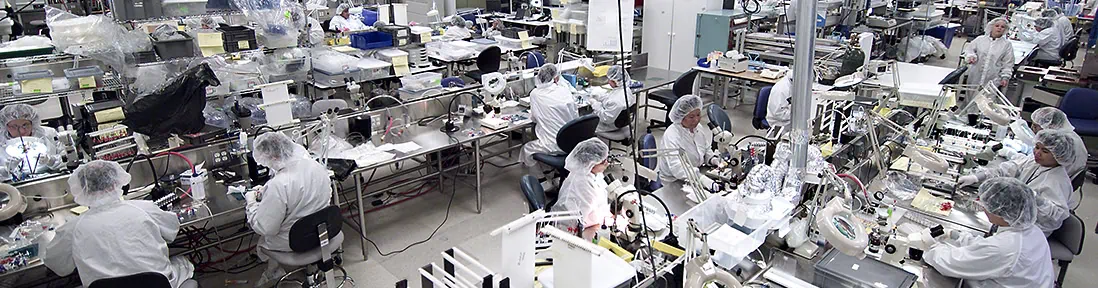

Eastprint, an East West Business’s team of touchfilm experts provide design and assembly services for capacitive touch user interfaces, providing the highest quality of system integration. Screen printing of silver circuit or transparent touch circuits can be assembled to in mold decorated overlays, injection molded plastics, while transparent circuits are commonly integrated with glass overlays.

We follow strict industry manufacturing and assembly standards in North American manufacturing facilities,. Our services include design and engineering assistance, as well as customization to meet the needs of unique applications. Contact us or request a quote for more information.