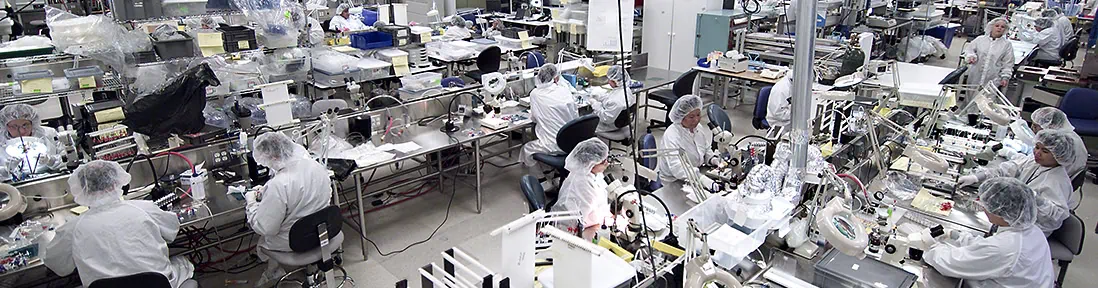

Eastprint Incorporated � an East West Company has been manufacturing custom membrane switch assemblies for clients in a multitude of industrial and medical applications for 40 years. We design our products, including high-quality graphic overlays and rubber keypads, using state-of-the-art manufacturing technologies and carefully selected materials that ensure maximum durability and reliability in any operating environment.

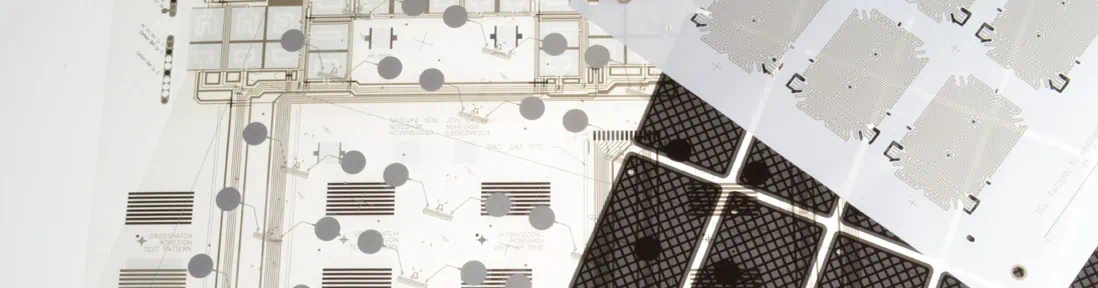

Our standard graphic and overlays for In Mold Decorating

can be customized with a wide variety of eye-catching graphic designs and finishes for aesthetic appeal and product identification. We utilize a number of screen printing, forming and molding techniques to help bring your graphic overlay project from concept to completion. These include:

- Automated and semi-automated sheet feeding

- Roll-to-roll printing

- Compression molding

- Roll and hand lamination

- Thermoforming

- Injection molding

Which Materials Are Best for Custom Graphic Overlays?

Each device design has unique specifications for touchscreens, membrane switches, or keyboard interfaces. Selecting the appropriate graphic overlay material depends on several factors, including:

- Functionality

- Textures and finishes

- Backlighting and other optional features

- Coating requirements

- Durability requirements

- Injection Molding Resin compatibility

Listed below are some of the most common types of overlay materials along with their unique properties and features.

Polyester

Polyester is one of the most durable and resilient polymer-based overlay materials available. Polyester possesses many desirable mechanical and chemical properties which make it highly resistant to a broad range of aggressive chemical compounds and harsh environmental conditions.

Chemical resistance is especially crucial when operating devices that may be at risk of chemical exposure from wash downs or product spillage. Most polyester blends also resist degradation from damaging UV rays, making this material ideal for membrane switches or keyboards in outdoor operating environments. Polyester overlays can also be coated with anti-microbial compounds for sanitary applications such as cleanrooms and medical/pharmaceutical laboratories.

In addition to chemical resistance, polyester’s mechanical properties make it resistant to extreme temperature conditions and abrasion. As a result, polyester graphic overlays are quite durable and possess a higher actuation life than other polymer-based overlay materials.

Polycarbonate

For applications where aesthetics matter, polycarbonate graphic overlays are the best choice. Although the chemical and mechanical properties of this material are inferior to polyester, polycarbonate’s strength lies in its customization potential.

Polycarbonate graphic overlays are available in a wider variety of thicknesses and are also easier to die cut, emboss and thermoform. This material offers many of the benefits of glass, such as superior UV resistance and high-gloss finish, at a significantly lower weight and cost.

Polycarbonate, however, tends to scratch easily and does not possess the same level of chemical resistance as polyester. Therefore, this material is not recommended for heavy use or industries where the risk of chemical exposure is high.

Vinyl

Vinyl overlays are renowned for their superior flexibility compared to other materials. Vinyl can be curved or contoured to conform to almost any irregularly-shaped surface. These overlays can be applied either directly to the surface of equipment, or they can be used as self-adhesive films for two-part panel construction.

Vinyl features a relatively low cost compared to polyester and polycarbonate overlays. This makes vinyl overlays especially cost-effective for bulk orders. However, it should be noted that this overlay material is not as durable as other materials, possessing only moderate abrasion, weather, and chemical resistance. Vinyl graphic overlays are best suited for use in less challenging environments where gloss, matte, or clear finishes are required.

PVC

Polyvinyl chloride (PVC) strikes a balance between aesthetics and durability, with properties that fall between polyester and vinyl. While PVC does not possess the strength of polyester, it can be textured to increase its abrasion resistance in moderately challenging environments, making it suitable for a limited selection of industrial machinery.

PVC graphic overlays can also accommodate a broad range of textures, finishes, and color combinations. Due to its mid-range properties, PVC offers the best cost-effective solution for switches and keyboards in products with medium- to short-term life expectancy.

Custom Keyboard Assemblies from Eastprint Incorporated � an East West Company

At Eastprint Incorporated � an East West Company, we have a great deal of experience providing graphic overlays for myriad applications, ranging from medical devices to appliances and industrial equipment. Our team of custom keyboard assembly experts can help you select the best overlay material to meet the function, durability, and aesthetic requirements of your unique application.

To find out more about our custom graphic overlay solutions and how they can improve your design or operation, feel free to contact us or request a quote.