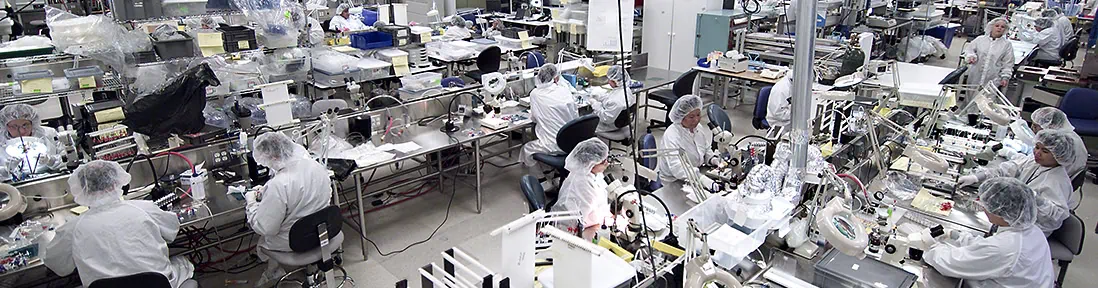

As an ISO 13485 certified company, our customers in the medical industry rely on Eastprint, an East West Business, an East West Business’s technical proficiency to build complex interface assemblies for critical patient care devices. We engineered and built a control panel assembly for a portable patient monitor and defibrillator. Our comprehensive engineering and manufacturing capabilities, combined with value added assembly and testing, allowed us to supply them with an end-to-end solution for this high-tech user interface.

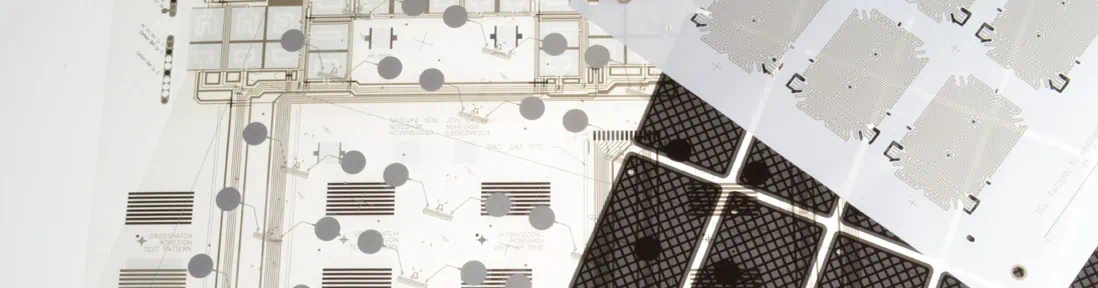

Built to IP55 protection standards, the control panel measured 8.750″ square. Highlights of the construction include a custom multiple-shot insert molded keypad, high-reliability Kapton circuitry, and integrated LED backlighting. Other features include tactile metal dome switches, LCD display, and an integrated speaker assembly. We designed and assembled custom wire harnesses to provide fail-safe interconnections between internal electronic components, and leveraged advanced robotics assembly for precise placement of the display and the lenses. Our additional activities included designing custom packaging solution for protecting the unit during shipment and storage.

We worked in close collaboration with the client’s international design team over a lengthy development cycle to engineer this product. Several of the major components were put through an exhaustive process of IQ/OQ/PQ verification and validation to ensure production complied with strict medical device regulatory requirements. Process verification included gauge R&R studies and PPAP Level III submission. We engineered this device in full compliance with RoHS and REACH directives to satisfy the requirements of a global marketplace.

With our engineering, quality management, and manufacturing expertise, we have formed a long-term partnership with this client. We provide user interface solutions for their leading brand of patient care devices that are in use around the globe by hospitals, EMS technicians, and military aeromedical personnel.

You can obtain further information about this project or our user interface contract manufacturing capabilities by contacting us today.

Portable Patient Monitor & Defibrillator Control Panel Assembly Project Highlights

- Project Description

Portable Patient Monitor and Defibrillator Control Panel Assembly

- Capabilities Applied/Processes

- Primary:

Compression Molding

Injection Molding

CNC Drill and Routing

Screen Printing

Copper Etching Kapton

Steel Rule Die Cutting - Secondary:

Robot Dispensed Gluing and RTV Dispensing

Component Assembly

SMT IR Reflow Soldering

Hand Soldering

Hand Lamination

Plastic De-Gating

Metal Stamping

- Primary:

- Equipment Used to Manufacture Part

Compression Molding Press

Injection Molding Press

High Speed Cylinder Screen Printing Press

Robot UV Dispense and Cure Station

Clam Shell Die Cutter

Custom De-Gate in Horizontal Platen Press

Various Custom Assembly Fixtures

- Overall Part Dimensions

8.750″ x 8.750″

- Tightest Tolerances

+/- .010″

- Material Used

Various: Silicone, Polycarbonate, Polyimide Kapton Circuitry, Polyester Shielding, Conductive Silver Inks, Acrylic adhesives, Metal Tactile Domes, Front and Side Fire SMT Leds, LCD display, Speaker, Metal speaker Bracket and wire harness assembly

- Material Finish

Various Velvet Textures

Anti-Glare Finishes

Matte Keypad Finishes

- Industry for Use

EMS, Hospital & Military Aeromedical

- In Process Testing/Inspection Performed

Full custom testing of LEDs, Switches, Displays, Speakers

- Delivery Location

United States

- Standards Met

- IP55

IQ/OQ/PQ

Gauge R&R

PPAP Level 3 - RoHS

Conflict Mineral

REACH

ISO 13485

- IP55