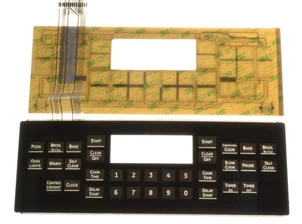

The capacitive glass touch panel highlighted here provides a robust, reliable, user interface in a consumer appliance application. Designed, engineered, and manufactured by the team here at Eastprint, an East West Business, it features a custom diffused front surface for backlighting of clear capacitive touch points. To effectively manufacture this complicated product, we leveraged our 30 years’ experience in screen printing and extensive knowledge of conductive ink systems and complex circuitry.

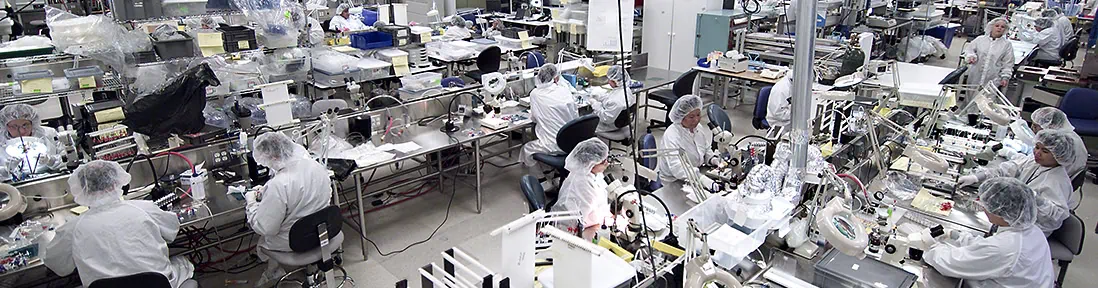

This high-quality product is the result of an intensive on-site collaboration with the client. Along with design-for-manufacturability, our engagement involved manufacturing process engineering, quality verification, PPAP Level III submission, and validation of our production equipment and procedures.

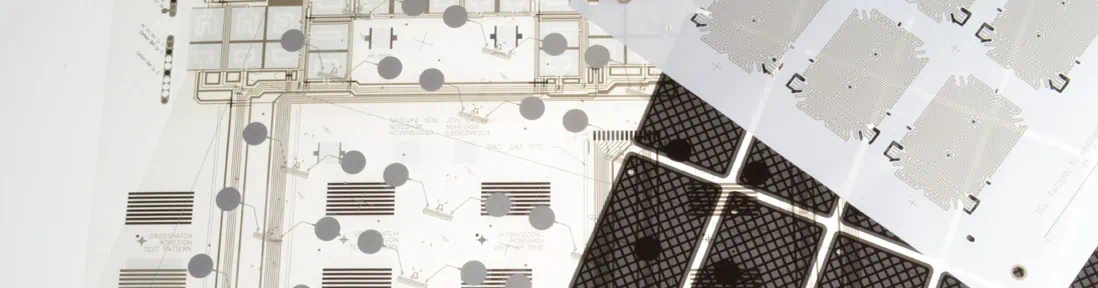

Featuring dimensions of 4.490″ in length x 12.310″ in length and incorporating a 6.50″ flexible tail, this part is composed of 16 total screen printed passes on both sides of a .007″ thick heat stabilized polyester film. Production involved the use of custom formulated transparent PEDOT inks as well as silver, carbon, UV stabilizers, and dielectric coatings. Our robust manufacturing capabilities combined with rigorous process controls allowed us to maintain precise and repeatable registration over all of the printed passes. Exhaustive quality testing included visual inspection as well as assessment of conductive resistance, clear conductive density, and conductor adhesion. We also designed and built a custom test bench for validating switch functionality.

By tapping into the full breadth of our technical expertise from the design, engineering, manufacturing, and quality standpoints, we produced this projective capacitive touchscreen switch cost effectively for our client. We continue to supply this product at the rate of 25,000 to 50,000 units annually, and we ship them to the client in custom-developed protective packaging.

To learn more about our projected capacitive switch technology or to discuss your project, contact us today.

Backlit Projective Capacitive Glass Touch Panel Project Highlights

- Project Description

Backlit Projective Capacitive Glass Touch Panel

- Capabilities Applied/Processes

- Primary:

Screen Printing

Steel Rule Die Cutting - Secondary:

Diffuser lamination

Mounting Adhesive Lamination

Connector Installation

- Primary:

- Equipment Used to Manufacture Part

- High Speed Cylinder Screen Printing Press

Clam Shell Die Cutting Equipment - Connector Application Machine

Custom Capacitive Touch Test Controller

- High Speed Cylinder Screen Printing Press

- Overall Part Dimensions

4.490″ x 12.310″ with 6.500″ flex tail

- Tightest Tolerances

+/-.015″

- Material Used

Various Heat Stabilized Polyester

Acrylic Adhesives

Lexan Diffuser

- Material Finish

Custom Diffused front surface for backlighting of clear capacitive touch points

- Industry for Use

Consumer Appliance

Range

- In Process Testing/Inspection Performed

- Conductive Resistance

Clear Conductive Density

Conductor Adhesion - 100% Switch Functionality via Custom Test Bench

Visual Final Inspection

- Conductive Resistance

- Delivery Location

United States

- Standards Met

- IQ/OQ/PQ

PPAP Level 3

Gauge R&R - RoHS

Conflict Minerals

REACH

- IQ/OQ/PQ